"uofime-2" (uofime-2)

"uofime-2" (uofime-2)

01/19/2016 at 12:48 ē Filed to: None

9

9

25

25

"uofime-2" (uofime-2)

"uofime-2" (uofime-2)

01/19/2016 at 12:48 ē Filed to: None |  9 9

|  25 25 |

For Christmas I got a fused filament rapid prototyping machine specifically an XYZprinting DaVinci Pro 1.0. This wasnít something I asked for or specifically wanted, in reality my opinion was that this type of machine is only useful for making non structural ďartĒ parts, but all the same I have one now, so I have to figure out what to do with it.

I had recently made tweeter brackets for my car out of sheet metal over the Christmas holliday and one of the guys from a local car club suggested that I should make those with the machine (probably because he was hoping for a set)

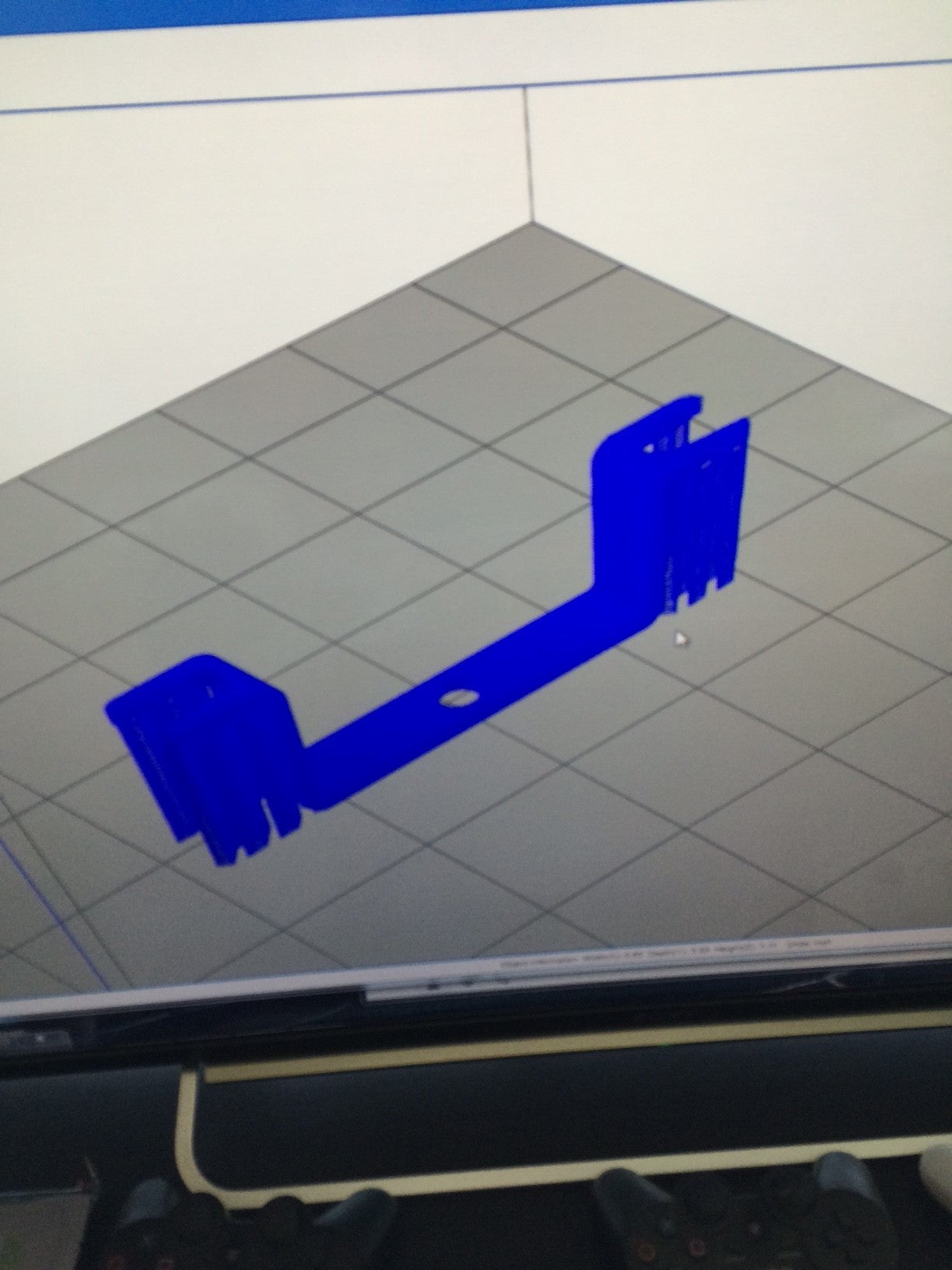

I remembered the dimensions from when I made the sheet metal ones, so I knocked out the model in a few minutes and proceeded to manufacture it in the laziest way possible with incredibly low expectations.

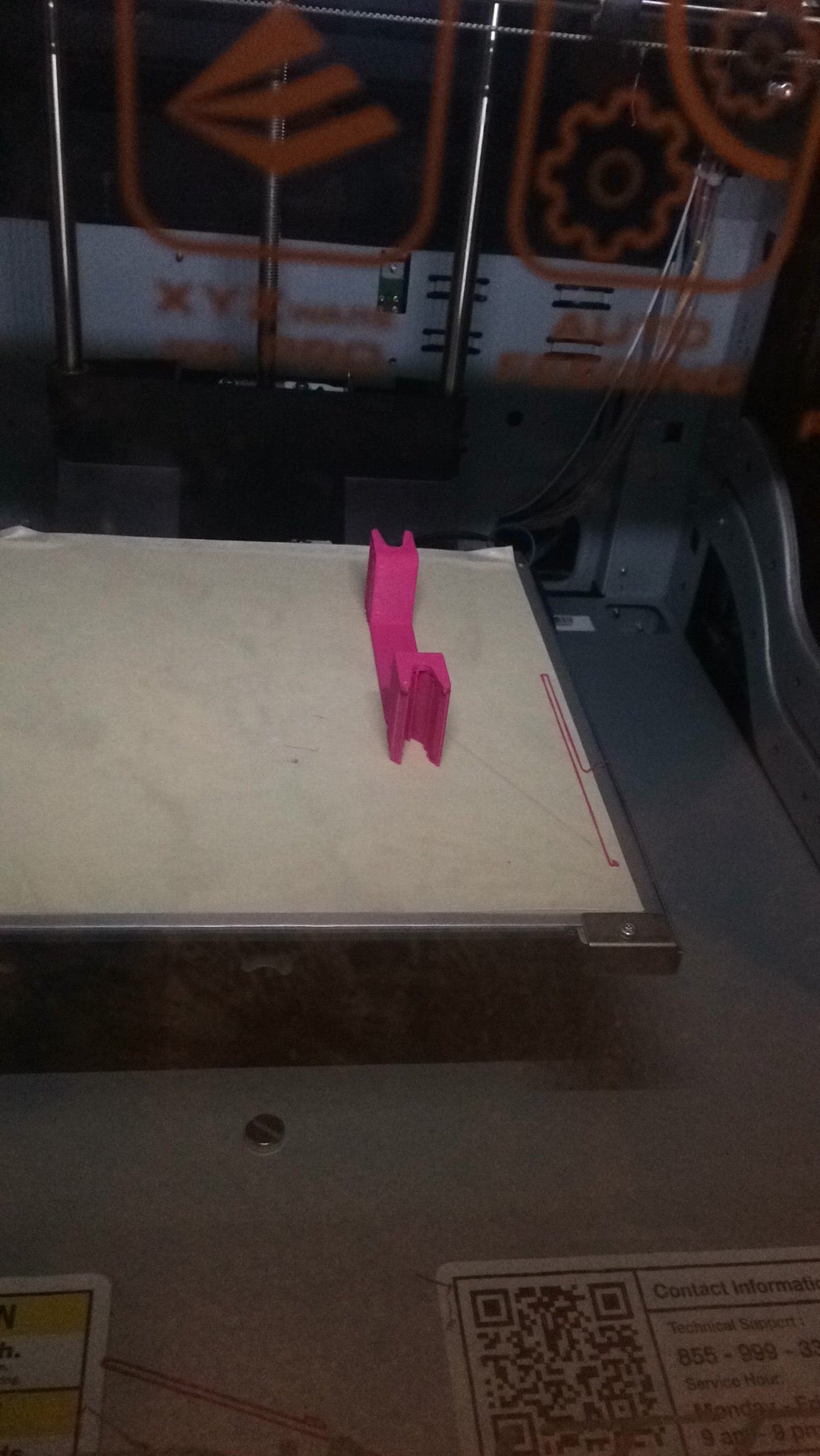

And hereís how it came out:

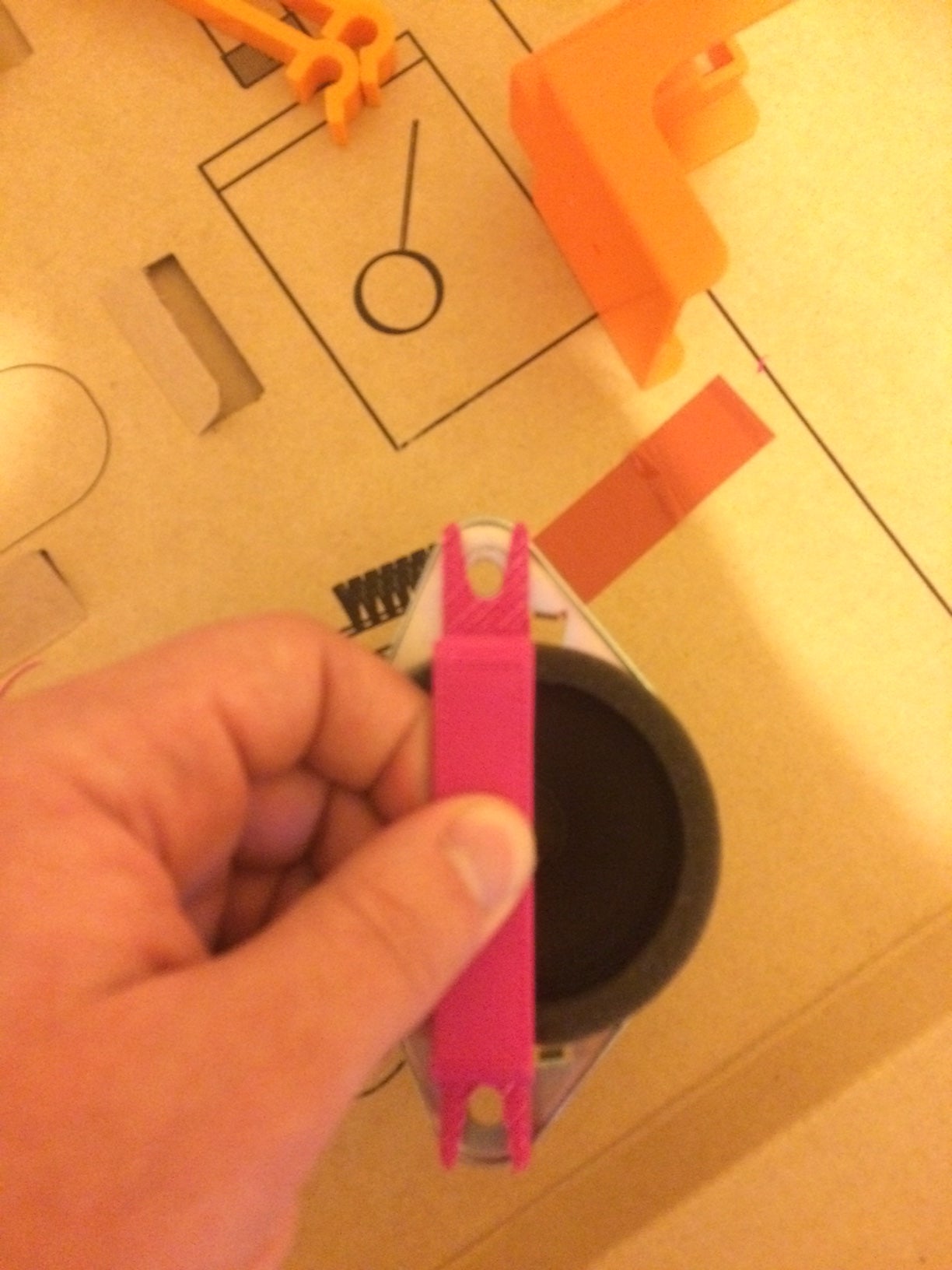

Not bad, the supports were a bit of a pain to knock off and left a bit of a rough surface. Time for a fit check with the old tweeter:

Also, not bad, looks like my ears are a little short. Time to tear my car apart and how it fits in-situ:

It fits! but as I suspected the ears are a bit short, the mounting hole for the tweeter in the center is a bit oversized and I really feel like the part overall could use some beefing up. All of those were pretty easy changes. I spent some time thinking on the best way to beef it up over all. Additive manufacturing means that itís easy to do a lit of clever things, but unfortunately a lot of those clever things interfere with the mounting interfaces, so I went with the worst option from a mechanical perspective and just widened the bracket a tenth

of an inch. Here it goes, revision 2:

The fit is much better and I was happier with the way the part feels overall. Here it is fitting much tighter with the old tweeter:

Then I went away skiing for the weekend I was thinking maybe I could sell these to locals at 10$ a pair Iíd make enough money to fund filament for further work with the machine. The fit is good and would make installation preposterously easy, as in a 5-10 minute job if you soldier the pigtail to the tweeter before hand (tweeters are a huge improvement for 15+wrx/stiís). However, Iím still not sure of the strength. Iíd love to have gone about testing with some kind of scientific method, but the fact is the loads on these in service are pretty hard to define and also really low. The highest chance of breaking is probably during installation.

So anyway this morning I was feeling particularity unsympathetic so I started twisting on the part until I broke it. The base and ears are X-Y planar and are surprisingly strong in bending, the legs that are X-Z planar suffer from the classic problem with fused filament machines, poor layer to layer bonding and snapped pretty easily.

So, whatís next?

Well I think Iím going to try printing the bracket on its side, the hole and slots are going to get screwed up with support material and Iím not sure how Iíll clean that, but that will definitely solve my legs breaking and hopefully the loss in strength for the rest of the part wonít be as much of an issue since it doesnít have as much of an ďarmĒ to be bent on.

Weíll find out how that goes in a couple of hours!

DirtyBird

> uofime-2

DirtyBird

> uofime-2

01/19/2016 at 13:00 |

|

you can get little saw blades for an x-acto knife

uofime-2

> DirtyBird

uofime-2

> DirtyBird

01/19/2016 at 13:02 |

|

HF sells hot knives for 20$ Iím going to get one of those next time Iím there, thatís technicaly the right way to remove this stuff

GTI Sprinks

> uofime-2

GTI Sprinks

> uofime-2

01/19/2016 at 13:06 |

|

Very neat. Itíll be cool to see what 3-d printers can do for the aftermarket in the near future. I know iíve seen some mk7 golf people making resized keyfobs for the keyless start keys.

DirtyBird

> uofime-2

DirtyBird

> uofime-2

01/19/2016 at 13:07 |

|

that works too, could look into tools used for scale model kits also, there actually quite a few. harbor freight even has little belt sanders

Andy Sheehan, StreetsideStig

> uofime-2

Andy Sheehan, StreetsideStig

> uofime-2

01/19/2016 at 13:10 |

|

I canít wait until this becomes more of a thing. I have some little broken plastic pieces for my CRX that I canít find anywhere, but someone who knows how to 3D print could probably make pretty easily.

shop-teacher

> uofime-2

shop-teacher

> uofime-2

01/19/2016 at 13:11 |

|

ďWell I think Iím going to try printing the bracket on its sideĒ

Thatís exactly what I was going to suggest. Should be stronger, and it will also print faster and waste less filament on support material.

You can sometimes strengthen the layer to layer bond by running your nozzle to table clearance just a teeeeeeeny bit tighter.

uofime-2

> shop-teacher

uofime-2

> shop-teacher

01/19/2016 at 13:23 |

|

Itís already really close, but Iíll try some experiments with how low I can go. Thanks for the suggestion.

uofime-2

> Andy Sheehan, StreetsideStig

uofime-2

> Andy Sheehan, StreetsideStig

01/19/2016 at 13:25 |

|

A lot of the molded parts in cars are really complicated. It will be a lot easier once cheap machines can do a seperate easily soulable support material that is easy to remove.

uofime-2

> DirtyBird

uofime-2

> DirtyBird

01/19/2016 at 13:26 |

|

Iíve been trying to use my dremel with several attachments (in addition to regular knives) but it doesnít do a good job and makes the surface worse.

shop-teacher

> uofime-2

shop-teacher

> uofime-2

01/19/2016 at 13:28 |

|

Itís amazing how small of an adjustment can make a difference. Of course that also goes for getting it too close ....

DirtyBird

> uofime-2

DirtyBird

> uofime-2

01/19/2016 at 13:29 |

|

ah that makes sense than

tromoly

> uofime-2

tromoly

> uofime-2

01/19/2016 at 13:36 |

|

Good luck with the DRMíd filament cartridge, I believe on Hackaday thereís a couple short write-ups of people who have reset the chips so they can load their own filament into the cartridges, I donít have a DaVinci so donít have an personal experience with it.

You should be able to lower the support density so that itís easier to remove post-print, in theory they should just snap off and you can then clean the surface with a knife or sandpaper. The only problem I see with printing on its side is it may split at the mounting holes, maybe do an acetone vapor bath to help fuse the layers on the surface? Canít remember if thatís for ABS or PLA though.

Have fun and keep us posted as you keep printing these.

uofime-2

> tromoly

uofime-2

> tromoly

01/19/2016 at 13:47 |

|

I have the Pro model with is the first that allows standard spools. Do you have any experience with who sells good ones? I read reviews on amazon and there are a lot of complaints of inconsistent extruding. I was halfway considering buying more of the XYZís stuff since they seem to have better quality despite the higher price point.

Frankly the price for all of these seem high, I work in the plastics industry and know what a kg of ABS goes for and it isnít anything like 25$....

Weíll see how it goes. I worked with a lot of nice machines while I was in school and like I said I have a pretty poor opinion of these type machines because of it, maybe I can do enough work to change my mind.

functionoverfashion

> uofime-2

functionoverfashion

> uofime-2

01/19/2016 at 13:58 |

|

This is what I need when I inevitably, one day, break one of the two plastic brackets that clamps down my roof box. The box is so old, Iím SURE the part is NLA. Fortunately, there are two. So I am hoping I can replicate the good one when one eventually breaks. Cool stuff!

tromoly

> uofime-2

tromoly

> uofime-2

01/19/2016 at 14:19 |

|

DaVinci finally got rid of the DRM? Must have missed that, itís a great thing. I donít remember what filament I used in the past, XYZ rings a bell but canít say for sure. But yeah, any filament is going to be pricey because itís a niche market, and itís not like people have many places to get it.

Iím still waiting for an SLA machine that can do a 12"x12"x12" volume to come along for a couple thousand dollars, thatíll be amazing.

Santiago of Escuderia Boricua

> uofime-2

Santiago of Escuderia Boricua

> uofime-2

01/19/2016 at 14:19 |

|

I made a bar clamp with mine. Just a rectangle with two bolt holes and a circular cutout. I canít get my printer to make anything that takes longer than 1-2 hours though, the extruder always jams

http://oppositelock.kinja.com/i-printed-someÖ

uofime-2

> tromoly

uofime-2

> tromoly

01/19/2016 at 14:47 |

|

I believe this is the first model they have made without it.

SLS is what I really would have wanted buy, but Iím not holding my breath till those become affordable since they probably never will be because since you need a full on oven, a laser and axis strong enough to deal with the weight of all the build material at full Z.

Those machines build really good parts and since the supporting material is just build powder it is pretty much infinitely recyclable with no processing and easy to just brush off

Spoon II

> uofime-2

Spoon II

> uofime-2

01/19/2016 at 14:51 |

|

Thatís awesome! I was actually considering getting one of these machines to make little parts for my various projects. Also, if you want to go hardcore you can use the plastic prototyped part to make a mold, and then cast a metal part based on that.

uofime-2

> Spoon II

uofime-2

> Spoon II

01/19/2016 at 14:57 |

|

I actually did that in a lab for one of my courses while I was in school four years ago. Beyond the difficulties of dealing with molten metal, casting itself is a pretty nuanced process if you want strong dimensionaly accurate parts

Spoon II

> uofime-2

Spoon II

> uofime-2

01/19/2016 at 15:03 |

|

Itís true! We only touched on the theory in school unfortunately, but itís something that I always wanted to try

uofime-2

> Santiago of Escuderia Boricua

uofime-2

> Santiago of Escuderia Boricua

01/19/2016 at 15:39 |

|

what kind of machine do you have? Mineís been trouble free, though Iíve only done 4 builds of like 1.5h each so far.

Iím still using the ďoverpricedĒ proprietary material cartridge that came with my machine. Iíve looked at buying more material and a lot of the material has bad reviews of this happening because the filament diameter goes over spec.

Itís got me thinking about building an inspection fixture to pull the filament through a go gauge to check it or just buying more of the ďover pricedĒ stuff

Santiago of Escuderia Boricua

> uofime-2

Santiago of Escuderia Boricua

> uofime-2

01/19/2016 at 15:47 |

|

Solidoodle press. Iím not the only one that has problems with it. There doesnít seem to be enough cooling to the extruder.

I canít even count how many times Iíve taken the extruder head apart to soak it in acetone to clean it out

uofime-2

> Santiago of Escuderia Boricua

uofime-2

> Santiago of Escuderia Boricua

01/19/2016 at 16:07 |

|

That has to be irritating!

My latest build at lunch didnít go well either, but I think I know how to fix it...

More problems to be solved, but hey Iím still enjoying the challenge for now.

Santiago of Escuderia Boricua

> uofime-2

Santiago of Escuderia Boricua

> uofime-2

01/19/2016 at 16:12 |

|

I havenít even tried anything with support material either. Plus I have to recalibrate the extruder offset every time I rebuild it

uofime-2

> Santiago of Escuderia Boricua

uofime-2

> Santiago of Escuderia Boricua

01/19/2016 at 16:26 |

|

Iím lucky, mine has an automatic calibration feature, but I want to try manually setting the offset so I can get it a little closer and try to improve my layer bonding as Shop-Teacher suggested here.